Automated Palletizing Robots: Let Workers Say Goodbye to Heavy Physical Labor!

Release time:

2025-08-18

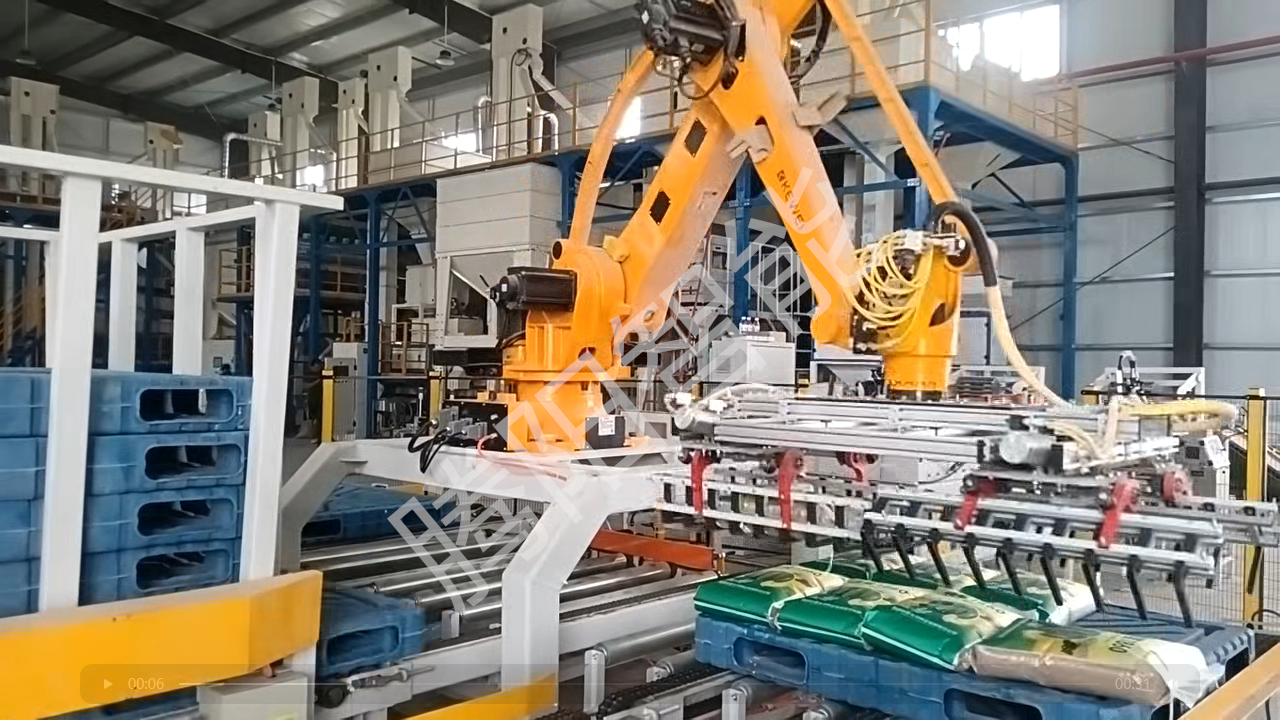

In modern manufacturing, palletizing is often one of the most arduous tasks on the factory floor. Workers repeatedly carry dozens of kilograms of goods daily, which not only reduces efficiency but also increases the risk of occupational injuries from prolonged bending and lifting. The introduction of automated palletizing robots is revolutionizing this situation!

In modern manufacturing, palletizing is often one of the most arduous tasks on the factory floor. Workers repeatedly carry dozens of kilograms of goods daily, which not only reduces efficiency but also increases the risk of occupational injuries from prolonged bending and lifting. The introduction of automated palletizing robots is revolutionizing this situation!

1. 24-hour efficient operation, increasing efficiency by 3-5 times

A single palletizing robot can handle 800-1200 boxes of goods per hour, significantly exceeding manual labor and operating reliably around the clock, significantly improving shipping efficiency.

2. Accurate and stable, eliminating cargo damage

Utilizing a high-precision servo system and 3D vision positioning, the robot ensures that each box of goods is neatly stacked, eliminating the problems of tilting and collapsing that can occur with manual handling, and reducing transportation losses.

3. Freeing up manpower and improving the working environment

Robots can replace 3-5 porters, freeing workers from heavy manual labor and allowing them to focus on more valuable roles such as equipment supervision and quality control. 4. Flexible Adaptability to Various Production Needs

Whether palletizing boxes, bags, or custom-shaped packages, the robot can switch between palletizing modes with simple program adjustments, meeting flexible production needs.

5. Reduce Long-Term Costs

Although there is an initial investment, robots can pay for themselves in 2-3 years. In the long run, they are more economical than manual labor and reduce the risk of workers' compensation.

Conclusion

Automated palletizing robots are not only a tool for efficiency but also a concern for worker health. Choosing automation means choosing a more efficient and user-friendly production future!

Latest News

High-Efficiency Warehousing: Stacking Speed Reaches New Heights!

In the modern logistics and warehousing industry, efficiency is the core competitive advantage. The new generation of high-speed palletizing systems, through technological innovation, pushes stacking efficiency to a new level, injecting powerful momentum into efficient warehousing.

2026-01-19

New Production Model for Cement Palletizing Robots

Facing the dual challenges of environmental upgrades and efficiency improvements in the cement industry, cement palletizing robots are driving the industry into a new era of intelligent production, completely transforming traditional cement warehousing operations.

2026-01-13

Safe and Efficient: Reshaping New Standards for Chemical Production

In the chemical industry, the safety and efficiency of raw material handling are always core concerns for enterprises. Chemical unpacking and feeding robots, with their professional explosion-proof design and intelligent control, are becoming a reliable guarantee for safe production in modern chemical companies.

2026-01-05

The ceiling of intelligent manufacturing has arrived.

In the fiercely competitive robot integration industry, Tengyang consistently prioritizes "innovation," investing 13% of its revenue in R&D, holding over 50 patents and 11 invention patents, and defining industry standards through technological breakthroughs.

2025-12-29

Plastic Pellet Unpacking and Feeding Robot: Making Raw Material Handling Smarter and More Efficient

In the plastics industry, the unpacking and feeding of raw materials directly impacts production efficiency and product quality.

2025-12-22

Comprehensive Upgrade of After-Sales Service System

As automated equipment becomes the core support of industrial production, the stable operation of equipment is crucial to a company's production lifeline.

2025-12-15