Founded

Annual Output

Floor Area

Exporting Countries

PRODUCT CENTER

The company's main products include robot palletizers, intelligent depalletizing and unpacking machines, fully automatic loading machines, winding machines, industrial control system engineering and automated production lines, etc.

KW1300M-3200 Load 300kg, 3200mm Palletizing Robot

KW1300M-3200 large load four-axis industrial robot. The wrist can carry a load of 300kg and the working radius can reach 3200mm.

KW1120M-2400 Load 120kg, 2400mm Palletizing Robot

KW1120M-2400 medium load four-axis industrial robot. The wrist can carry a load of 120kg and the working radius can reach 2400mm.

KW1007B-740 Load 7kg, 740mm Handling Robot

KW1007B-740 small load six-axis industrial robot. The wrist can carry a load of 7kg and the working radius can reach 740mm.

KW1004B-580 Load 4kg, 580mm Handling Robot

KW1004B-580 small load six-axis industrial robot. The wrist can carry a load of 4kg and the working radius can reach 580mm.

KW1030M-1835 Load 30kg, 1835mm Palletizing Robot

KW1030M-1835 small load four-axis industrial robot. The wrist can carry a load of 30kg and the working radius can reach 1835mm.

KW1080B-2700 Load 80kg, 2700mm Industrial Robot

KW1080B-2700 medium load six-axis industrial robot. The wrist can carry a load of 80kg and the working radius can reach 2700mm.

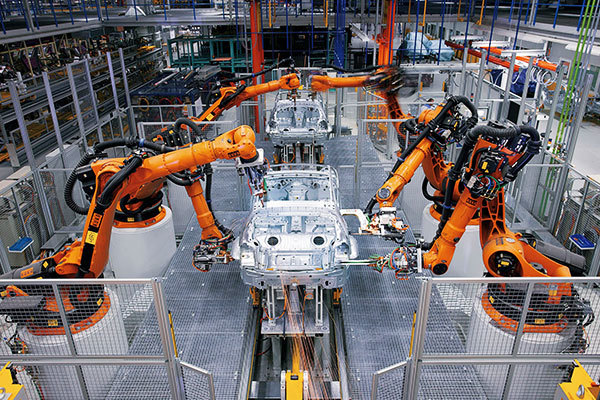

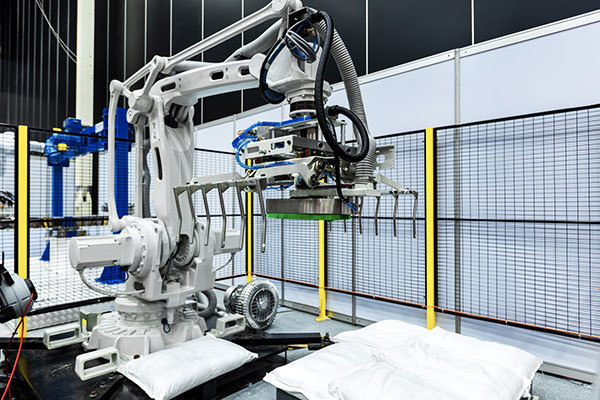

Palletizing robot assembly line

Through highly integrated automation equipment, production efficiency and product quality are greatly improved; Equipped with intelligent control system to calculate the optimal production plan; With good flexibility and scalability, it can be adjusted and optimized according to production needs.

Palletizing robot assembly line

Through highly integrated automation equipment, production efficiency and product quality are greatly improved; Equipped with intelligent control system to calculate the optimal production plan; With good flexibility and scalability, it can be adjusted and optimized according to production needs.

ABOUT TENGYANG

Shandong Tengyang Intelligent Equipment Co., Ltd. is located at the foot of Mount Tai, the most important five mountains, the hometown of construction and installation, and the capital of practicing "craftsman spirit" - Feicheng, Shandong. The company is a high-tech enterprise, a gazelle enterprise, a key enterprise in intelligent equipment manufacturing, and an industry-university-research cooperation unit of Shandong University integrating product research and development, manufacturing and sales.

View More +

Applications

Applications

Applications

Applications

Applications

Applications

HONOR

2019 14th China (Shandong) International Equipment Manufacturing Expo Gold Award

Tai'an Municipal Specialized and Innovative Small and Medium Enterprises

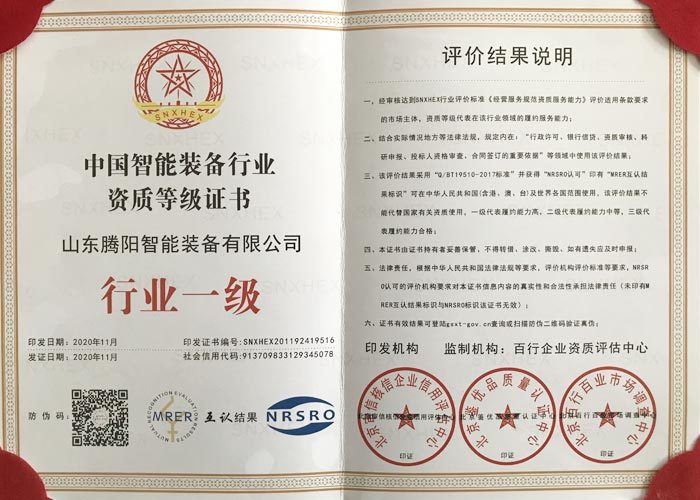

China Intelligent Equipment Industry Qualification Certificate Industry Level 1

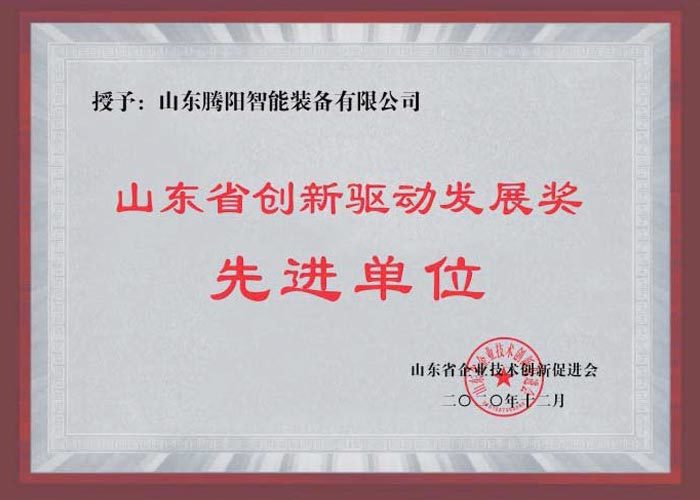

Shandong Province Innovation-Driven Development Award

National first-class enterprise

Top 50 Technologically Innovative Enterprises in Tai'an

Shandong famous brand

Advanced Unit

WHY CHOOSE US

The products are sold to more than 30 provinces, municipalities, and autonomous regions, and are also exported to Vietnam, Africa, North Korea, Malaysia, Mexico, etc. Countries and regions, annual production and sales of more than 2,000 sets of various types of intelligent equipment.

QUALITY ASSURANCE

We have carried out strict inspection of every part and product, trying to have no quality problems in the hands of customers.

GOOD SERVICE

Answer the customer's question within8 hours, and the service engineer will be on standby 24 hours a day.

PRICE ADVANTAGE

Factory direct sales, no middlemen price difference.Advanced production equipment and manufacturing technology

RICH EXPERIENCE

The products are sold to more than 20 provinces, cities and autonomous regions in China and exported to dozens of countries in Africa and Southeast Asia.

NEWS CENTER

The company's main products include robot palletizers, intelligent depalletizing and unpacking machines, fully automatic loading machines, winding machines, industrial control system engineering and automated production lines, etc.

Column Palletizer: A High-Efficiency Solution Breaking Space Constraints

In modern factory layouts, space is often a key factor limiting production efficiency. Column palletizers, with their unique vertical structure design, are becoming the ideal choice for space-constrained production environments, redefining the possibilities of compact automated palletizing.

Building an Efficient and Neat Automated Palletizing Line

Faced with tens of thousands of cartons of products daily, how can you achieve efficient and neat palletizing operations? Carton palletizers, with their professional performance and stable operation, are the best choice for modern warehousing and logistics!

11-24

2025

Vertical Palletizer: A High-Efficiency Palletizing Solution for Space-Confined Factories

In modern factory production, space utilization directly impacts overall operational efficiency. The vertical palletizer, with its unique vertical structure design, is becoming the ideal choice for companies with limited space!

11-17

2025

Industrial Robots Enable Unmanned Factories

In the wave of intelligent manufacturing, unmanned factories are moving from concept to reality. Industrial robots, as core equipment, are accelerating this revolutionary transformation with their superior automation capabilities.

11-10

2025

Corn Germ Palletizing Robot: The Intelligent Handling Expert Safeguarding Nutrition

In the corn deep processing industry, corn germ, as a high-nutritional-value raw material, presents a dual challenge of hygiene and efficiency in its palletizing process. Corn germ palletizing robots, with their professional performance, are becoming the preferred solution for industry upgrades!

11-03

2025

Column Robots: Intelligent Material Handling Experts with Big Impact in Small Spaces

In modern factories where space resources are increasingly scarce, column robots, with their unique structural advantages, are becoming a rising star in the field of intelligent material handling! This robot, designed specifically for compact spaces, is redefining the infinite possibilities of efficient warehousing.